Gear-Changing

There is an easy way and there is a hard way. The easy way is to just weld a length of round steel 13mm thick to the butt of the old foot operated gear selector, and have it so it is close at hand. All one has to do then is to get a round piece of wood/ aluminium and to bolt it to the top of the new gear change lever. And that's all there is to that way.

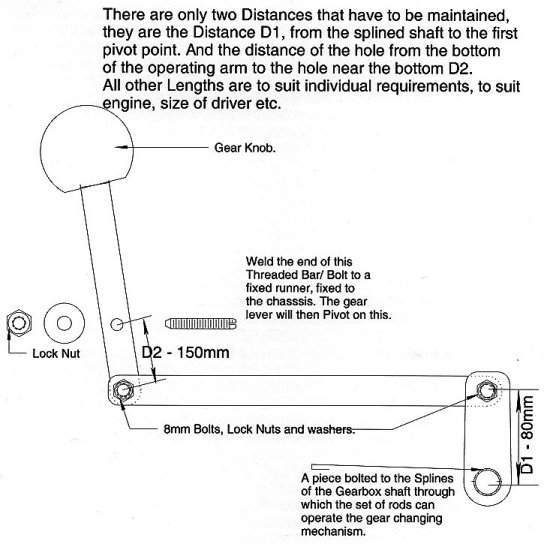

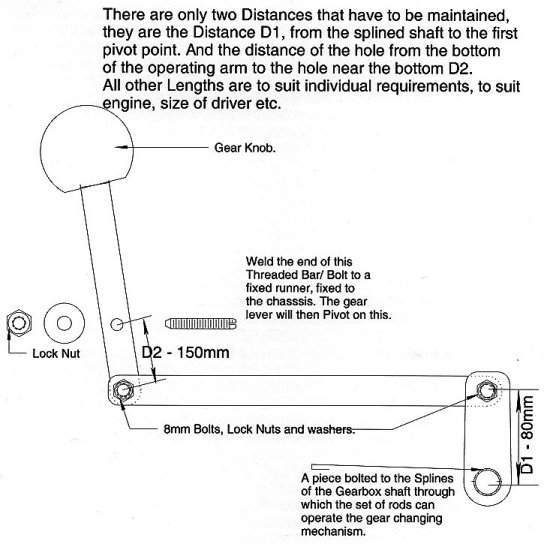

However if you have a sensitive gearbox, that is that gear changing is too delicate then a series of rods should be used to gear down the rotation of the gear selector shaft. It is more easily followed in the diagram. Also another benefit is that you can have the gear lever really close to hand for positive and quick gear changing. Another thing is to try and keep the actual gear changing operating arm as small as possible in length. Too long and it will give terrible gear change. A nice short stubby operating arm and you will feel gears been selected more positively and smoothly. You can experiment around with D1 and D2. Remember making D1 longer then you will have to move the operating arm more to get it to go into gear. But if it is too short then the gear changing will be too delicate. You can also change D2 too, however it's affects are in reverse of that with D1. i.e.. making it longer will make gear changing too delicate and too fast for comfort. The sizes given are a very good approximation for all typical engines and gearboxes.